Efficient filtration: the key element of industrial vacuum cleaners

24/01/2021

_601029f5bd653.png)

During the use an industrial vacuum cleaner raises dusts, particles and materials with different grain size characteristics. It is essential that the vacuum cleaner retains all these materials inside and prevents them from being reintroduced into the environment through the outgoing airflow, so as to:

-

Preserve the environment's cleanliness

-

Protect workers' health: Breathing or being exposed for long periods of time to very fine or harmful dust (such as silica dust or lead) inevitably leads to skin and respiratory symptoms or problems.

-

Eliminate all types of contamination and comply with current regulations

-

Minimize the possibility of explosion in hazardous areas or in the presence of combustible dust

For this reason the cleaning equipment used must be equipped with appropriate progressive efficiency filtration systems capable of blocking and retaining all types of dust.

PRIMARY AND ABSOLUTE FILTERS AND MULTI-STAGE FILTRATION: LET'S GET TO KNOW THEM BETTER

With so many vacuum cleaners and filters, it can be hard to tell which of these will really help you filter dust and particles and ensure absolute safety in the workplace. This is where our guide comes in.

Delfin vacuum cleaners are equipped with high quality filters of different types depending on the use they will cover in the company and unlike common vacuum cleaners, industrial vacuum cleaners are equipped with more than one filter inside them creating the above-mentioned "multi-stage filtration" where several filters with different functions combine to ensure efficient and safe filtration. The primary or main filter has the task of collecting most of the dust and material sucked in before it re-enters the environment. It has an additional function to protect the motor avoiding wear and tear and problems.

These filters for dust collection can be in class L, M or H and they differ according to the use as we will see later on..

To ensure further filtration to protect the most crucial parts of the machine, Delfin supplies its vacuum cleaners with absolute filters with HEPA certification. Positioned close to the head of the vacuum cleaner, they provide greater protection for the motor, extending its operating life and ensuring that even potentially dangerous and fine dust is collected.

APPROPRIATE DUST AND FILTERS: HOW TO CHOOSE?

The size of the particles that form the vacuumed material has an essential importance in finding the right filter to use in your vacuum cleaner.

According to the standard DIN -EN 60335-2-69 / 2015 and IEC 60335-2-69 / 2012 dusts are classified into three main categories based on the maximum concentration allowed in a working environment before they become harmful to operators: Class L (low), M (medium) and H (high).

Powder formulation and classification:

Class L ≤ 1.0% Dusts with maximum allowed concentrations (MAC) > 1 mg/m³.

They represent a moderate risk to the operators and the filter used in this case retains more than 99 % of the dust with a particle size smaller than 3 microns.

Class M < 0,1% Dusts with maximum allowed concentrations (MAC) ≥ 0,1 mg/m³.

They represent a medium risk, the filter traps more than 99,9 % of the dust with a particle size of less than 2 microns..

Class H < 0,005% Dusts with maximum allowed concentrations (MAC) < 0,1 mg/m³.They pose a high risk for health, the corresponding filter retains more than 99,995 % of dust with a particle size of less than 1 micron (including cancerous dust).

How to classify filters:

Depending on their plot that guarantees a certain level of filtration, the filters are in turn classified in L, M and H categories.

The different classifications indicate which vacuum cleaner is best suited to the desired use.

L-type filter vacuum cleaners remove 99% of the dust with a size of 3 micron. They are used in general cleaning applications, where you come into contact with dust that does not cause a high health risk, such as plaster dust and woodworking dust.

The vacuum cleaners with type M filter, capture 99% of the dust with dimensions of 1 micron, cover a wide variety of applications, are mainly used in companies that require high filtration efficiency as in the food industry, pharmaceutical and surface treatment. The most common extracted powders are ceramic, plastic, paint and food powders.

Vacuum cleaners with Class H filter offer a higher filtration capacity than the previous ones, they vacuum and capture up to 99.995% of the dust with a size down to 0.18 micron, they are generally used when working in environments with highly cancerous dusts such as lead, carbon, tar, nickel, cobalt, copper and silica.

VARIOUS FILTERS FOR VARIOUS NEEDS AND APPLICATIONS

Let's therefore analyse together the different types of filters offered by Delfin to ensure that the working environment remains clean and safe at all times. When choosing the filter, you should also take into account the air load that the filter will receive in the intake.

This figure is called filter unit load, which is how much air passes through the filter at full engine speed. The result is obtained by dividing the air flow rate by the filter surface area (m3/h / m²), all outcomes lower than 200 are positive values.

Polyester star filter

Polyester star filter

It is one of the most common filters in the field of industrial extraction, thanks to its high filtration and its large surface area, dimensionable to 14, 16 or 20 pockets depending on the vacuum cleaner or vacuum requirements.

Polyester cartridge filter

Polyester cartridge filter

The cartridge filter is a filter commonly used in vacuum cleaners with generic applications such as MTL 202, Pharma and 301 DUST. It allows the safe suction of materials down to 1 micron. Depending on the application it can be realized in pleated paper, with synthetic products or with PTFE coating to facilitate the detachment of trapped dust.

Antistatic filter

Antistatic filter

It is a filter much like the previous ones, but it contains internally a wire mesh that creates continuity with the vacuum cleaner and avoids the creation of accumulated electrostatic charge.Ideal for suction of materials that can generate static electricity, with consequent creation of sparks. A must when vacuuming in hazardous areas or removing conductive materials.

PTFE coated filter

PTFE coated filter

The filter with Polytetrafluoroethylene (abbreviated PTFE) coating is designed for applications that come into contact with clogging dust: the membrane with which it is coated makes it easier to detach the dust, causing it to fall out during filter cleaning operations and not allowing it.

HEPA absolute filter

HEPA absolute filter

HEPA stands for "high efficiency particulate air". Filters of this category have an essential function within vacuum cleaners because they capture most of the environmental contaminants before they can reach the engine head and ensure high levels of cleanliness. They have a filtration efficiency of 99.995% at 0.18 micron. The absolute filter is always installed as a secondary filter to stop any dust or residue that has bypassed the protection of the primary filter before it reaches the engine head.

Filter bags

Filter bags

Used in small vacuum cleaners they are able to capture the most common and coarse dust. On its inside it has a metal mesh that makes them antistatic. It guarantees a safe disposal avoiding any contact with dust.

PPL bag filter

PPL bag filter

The special polypropylene mesh (PPL) allows liquids to be filtered, also shielding from foams and other solid objects that are vacuumed. Available for filtration up to 100 microns.

OWR filter

OWR filter

Commonly called hydro-repellent filter, it was created to protect the engine from the oily fogs that during the discharge of air are able to overcome the common primary filters and eventually reach the motor of the vacuum cleaner. This filter is widely used for applications in the engineering industries.

Activated carbon filter

Activated carbon filter

Filter with the special feature of being able to capture bad smells and prevent them from spreading into the surrounding environment.

NOMEX filter

NOMEX filter

Nomex filters have been treated to withstand temperatures up to 180°C. Used in applications where the product to be removed is mixed with very hot air, such as applications in bakeries or in environments working with hot ovens..

Motor cooling filter

Present in the engine header, it makes the incoming air clean, filtering it before it can reach the engine to cool it down. It offers additional protection to the engine and avoids the risk of damage.

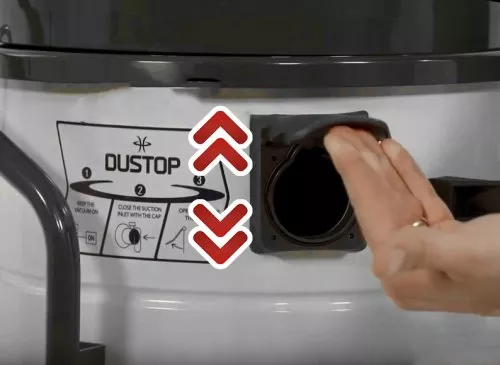

CLEANING AND MAINTENANCE

All the filtering features we have seen so far guarantee high efficiency in different applications. However, in order to maintain a constant level of vacuum performance and efficiency over time, the vacuum cleaner must be equipped with an integrated filter cleaning system suitable for the filters provided.

The filter cleaning systems are located inside the vacuum cleaner body and do not require extraction of the filter by the operator. They are divided into three macro categories:

Manual, semi-automatic and automatic mechanical system (for more details see the specific article)

Everything we have seen up to now shows how Delfin equips its vacuum cleaners with quality filters to ensure massive levels of filtration and hygiene, while guaranteeing production quality and operator safety.